Environmental & Materials Science

Microplastic Capture & Analysis

Our microplastic filters simplify the capture and analysis of environmental microplastics for local water authorities, governmental regulators, and academic researchers.

The incidence of microplastic analysis in the environment and in animal and human health studies has skyrocketed in the past decade, and technology must evolve in order to meet this demand.

Plastic products are used in a considerable volume of food packaging, household consumer products, and industry-level shipping. The breakdown of these plastic products continues to release micro- and nanoplastic particles into the environment. As a result, these particles make their way into food, and into human tissues. Incidence reporting, monitoring, health, fate, and transport studies require a reliable method to capture these microplastics in addition to allowing for the ease of particle analysis once captured.

How to test for microplastics

SiMPore’s all-on-one membrane design simplifies the process: filter the sample and analyze the captured particle on the membrane via multiple forms of spectroscopy, optical microscopy, or glass transition testing.

SiMPore’s microplastic filters are well-suited for the filtration, capture, and analysis of microplastics in environmental and municipal water samples, air samples, and samples containing suspended solids. No matter the sample type or composition, simply filter the appropriate volume onto the membrane, and collect the results with your preferred analysis method.

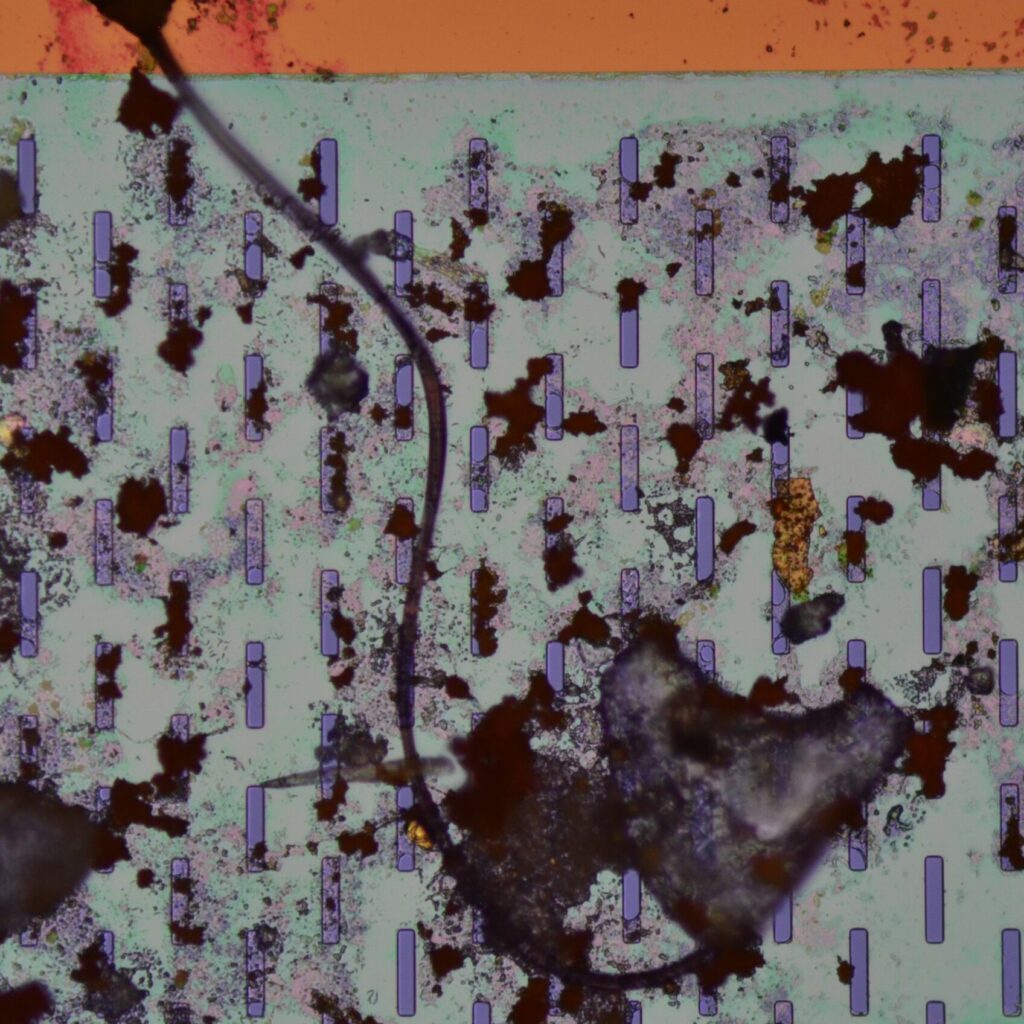

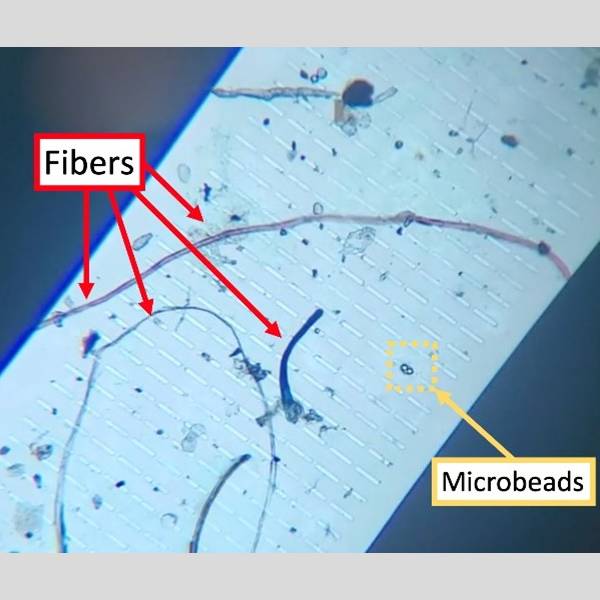

Capture and observe microplastic particles

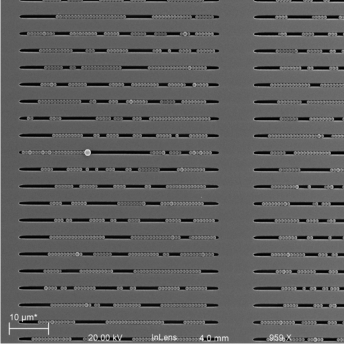

Our microslit filters have filtration cut-offs from 10 microns to 0.5 microns, allowing the observation of the smallest sized particles of concern.

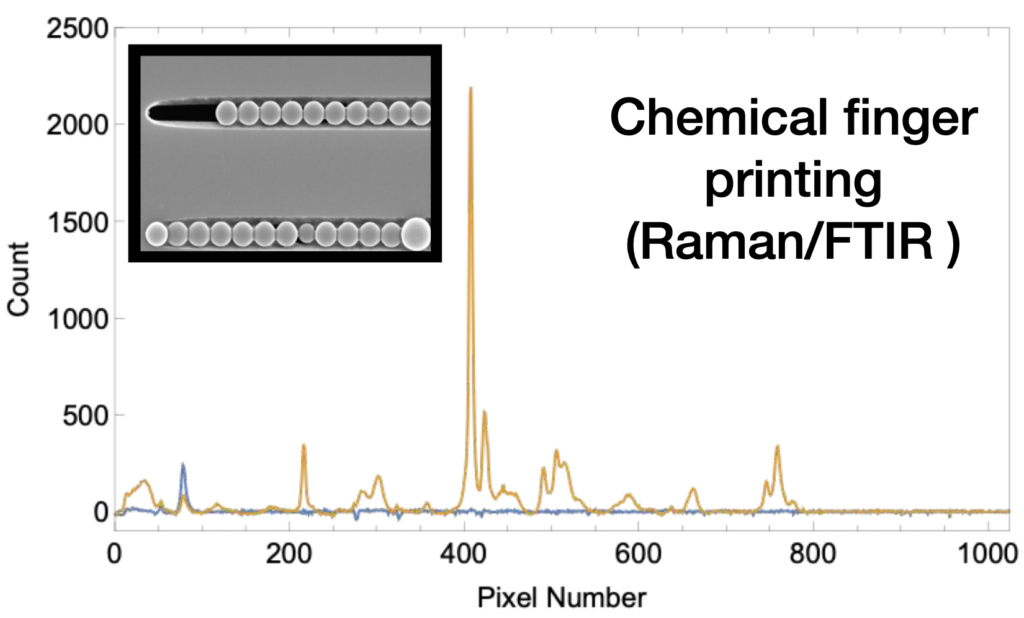

Microplastic analysis via spectroscopy

Gold-coated Microslit Silicon nitride membranes enable filtration directly onto an optical, IR, or Raman spectroscopy-compatible substrate.

- Avoid time-consuming and contamination-prone transfer steps

Plastic Microparticles were captured and suspended within the pores of a SiN microslit membrane. A Raman spectrogram was captured and correctly identifies the material as polystyrene.

Our Microplastic Filter Materials

Our filters for microplastics analysis feature a range of filter cut-offs, fast flow rates, and are available with and without metal-coatings for spectroscopy compatibility.

Microslit Silicon Nitride

Faster flow rates

Filter liters of clean water samples in minutes.

Plastic-free background

Flat and uniform microslit silicon nitride membranes offer an even imaging plane that is free of background polymeric signal.

Convenient handling format

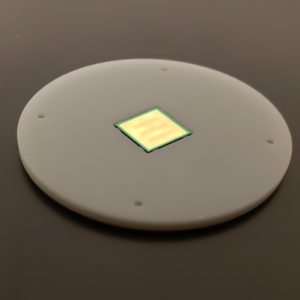

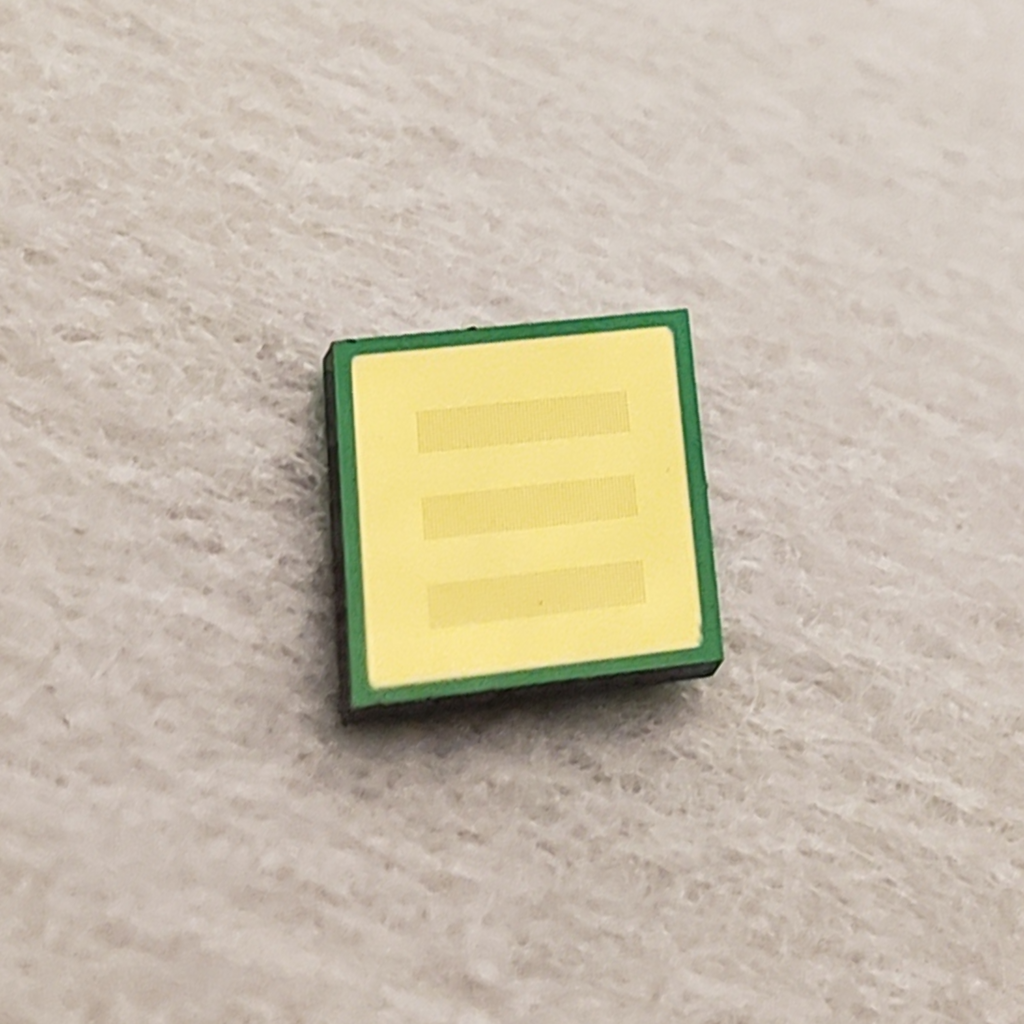

Easily handled 25 mm diameter filter discs fit standard vacuum filter apparatuses.

Choice of filtration cut-off

Choose to retain particles from 10 µm to 0.5 µm and serially filter through decreasing cut-off filters and size-fractionate and analyze to single micron-scale particles.

Gold-Coated Silicon Nitride

Infrared & Raman microscopy compatible

All the same properties as uncoated microslit silicon nitride but with an additional high quality and highly reflective gold coating.

Why Choose SiMPore for Microplastics Research

- SiMPore’s membranes are patterned with a consistent and predictable pore geometry, which is guaranteed to aid in the simplification and ease of both manual and automated particle counting and identification. Increase confidence in your results and reduce the incidence of error – know that every subsection of each membrane will be the same in reported porosity, pore size, and pore count.

- The wide variety of available pore sizes means that researchers can explore particles of greatest interest, from 10 microns to 0.5 microns.

- Membranes can be coated with aluminum, palladium, or gold, ensuring that multiple particle analysis methods for research needs can be met using the same membrane filtration sample. In addition, membrane base materials can be comprised of pure silicon, silicon dioxide, or silicon nitride. SiMPore can work with you to custom-create a membrane type, coating, pore size and porosity to best suit your microplastic analysis, monitoring, reporting, and research needs.

- Optical microscopy, IR, and Raman spectroscopy can be conducted on the same appropriately coated substrate, in addition to determining the glass transition temperatures of captured microplastics. With a custom-order metal coating thickness available for 50-200nm, know that the substrate background signal will reliably not interfere with your spectroscopy analysis.

- Membranes can withstand high acidic, alkaline, oxidative, and enzymatic conditions, cutting out the need for time-consuming and contamination-prone particle transfer steps. Capture your particles on a single membrane, and conduct all your particle analysis streams on that same membrane.

- The rigid, robust design is user-friendly, requiring no additional support structures to keep the membrane in place. Never worry again about your membranes folding, wrinkling or deforming at any point during the sample processing stream. Handling of the filter disk series requires no training or practice, allowing researchers of all experience levels can receive reliable results they can trust.

- The filtration surface area fits within 9mm2, allowing for faster processing and analysis of results – particle counting and identification is a breeze, reducing the need to spend lengthy analysis sessions hunting for particles of interest.

- Each membrane is completely flat, no matter how long it’s been filtered for, or how many particles are on the surface. No need to spend time re-focusing during microscopy for every new field of view – automated imaging results will return crystal clear across the entire membrane surface.

Shop Microplastic Filter Products

-

Filter Disk Sets – Gold Coated$669.50

-

Filter Disk Sets – Noncoated$618.00

-

Microslit Membrane ChipsPrice range: $566.50 through $606.50

-

Microporous Membrane Chips$566.50